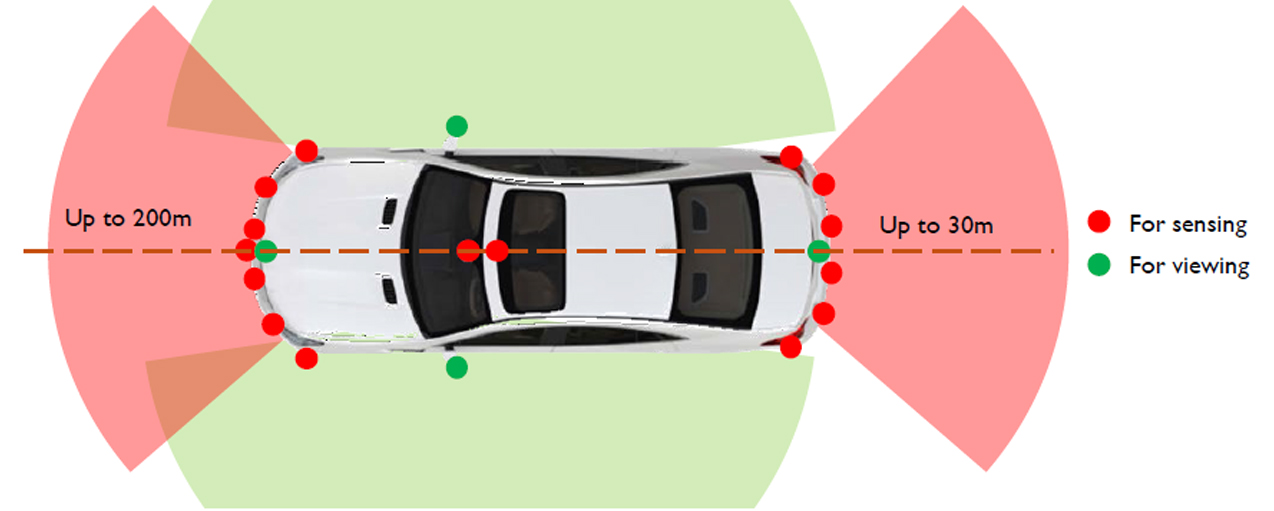

Evolving 3D sensing technology will play an increasingly important role in improving the safety and functionality of smart and autonomous vehicles. In-vehicle LiDAR (Light Detection And Ranging) sensors are expected to complete the full suite of sensors required for highly automated driving solutions.

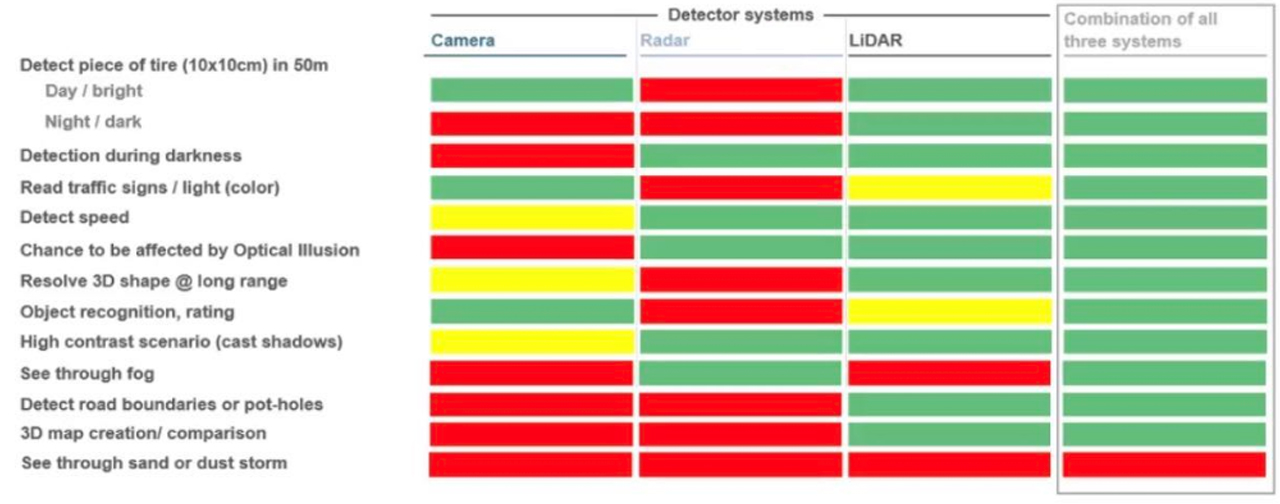

Advantages of LiDAR over vision and mmWave radar

As a result, as many as 100 different companies have received around billions of dollars in investment to develop high-resolution lidar sensors using a variety of new technologies such as different laser diodes, scanning methods, integrated chipsets, receiver technology, and more.

LiDAR becomes the core sensor for unmanned driving

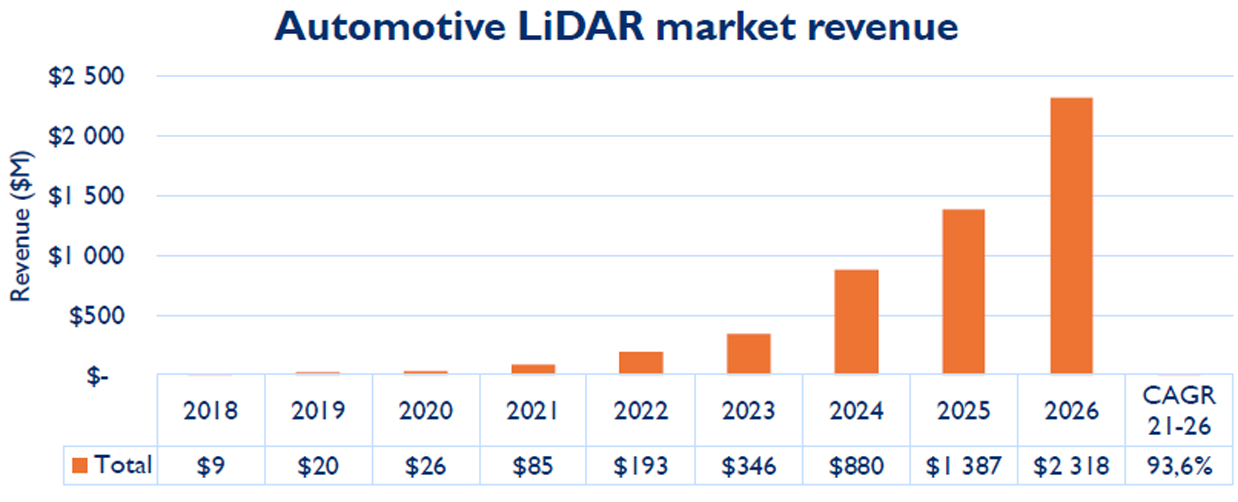

Vehicle LiDAR Market Scale Forecast Source: YOLE

The market forecast of YOLE in France shows that the automotive lidar market is expected to experience an explosive growth in 2024. It is expected that the market size will reach 2.3 billion US dollars by 2026, and the compound growth rate from 2021 to 2026 will reach 93.6%. In order to avoid the damage of visible light to the human eye, the laser wavelength selected by lidar is generally not less than 850nm. At present, the mainstream lidar mainly has two wavelengths: 905nm and 1550nm.

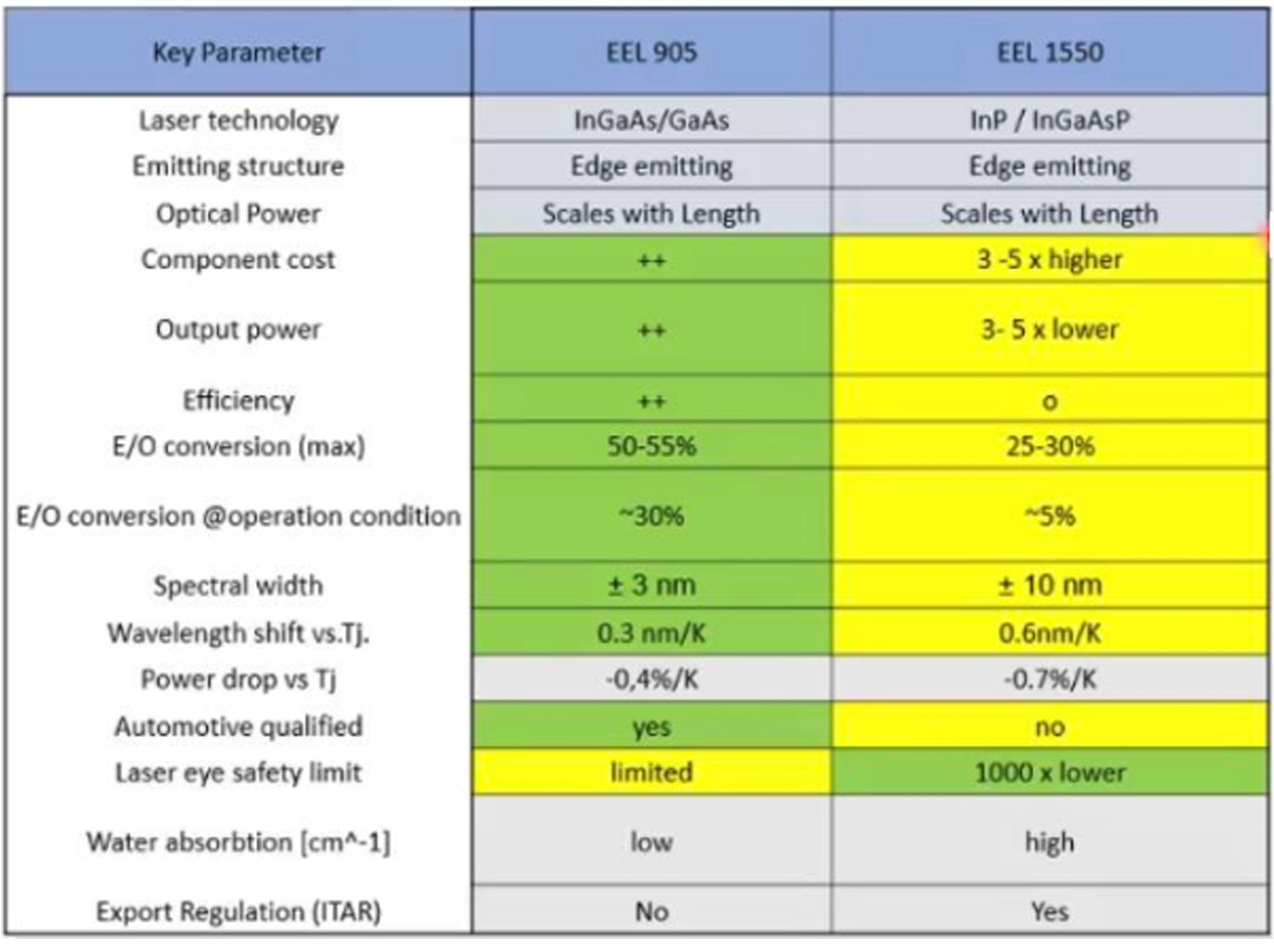

● 905NM

Since the 905nm lidar receiver can directly use the lower-priced silicon material, the cost is more controllable, and the 905nm lidar has become the wavelength selected by the most mainstream lidar.

However, the wavelength of visible light that can be recognized by the human eye is at 390-780nm, and the laser light in the 400-1400nm band can pass through the vitreous and focus on the retina without being absorbed by the lens and cornea. Causes photoreceptor cell damage. Therefore, in order to avoid damage to the human eye, the 905nm lidar needs to transmit power within a harmless range.

Because of this, the detection distance of the 905nm laser is also limited.

● 1550NM

Compared with the 905nm laser, the 1550nm laser will be absorbed by the lens and cornea of the human eye and will not cause damage to the retina. Therefore, the 1550nm laser radar can emit higher power and the detection distance can be farther.

However, the 1550nm lidar cannot use conventional silicon absorption, and needs to use the more expensive indium gallium arsenide (InGaAs) material, so it will be much more expensive than the 905nm lidar.

法布里—珀羅邊發(fā)射激光器 EEL

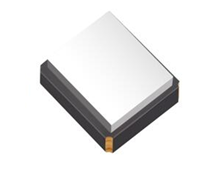

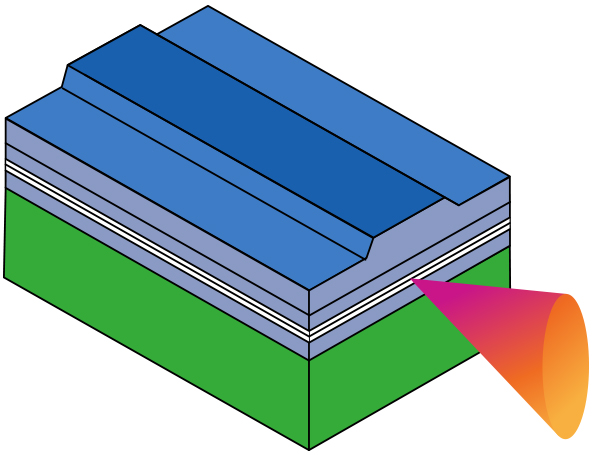

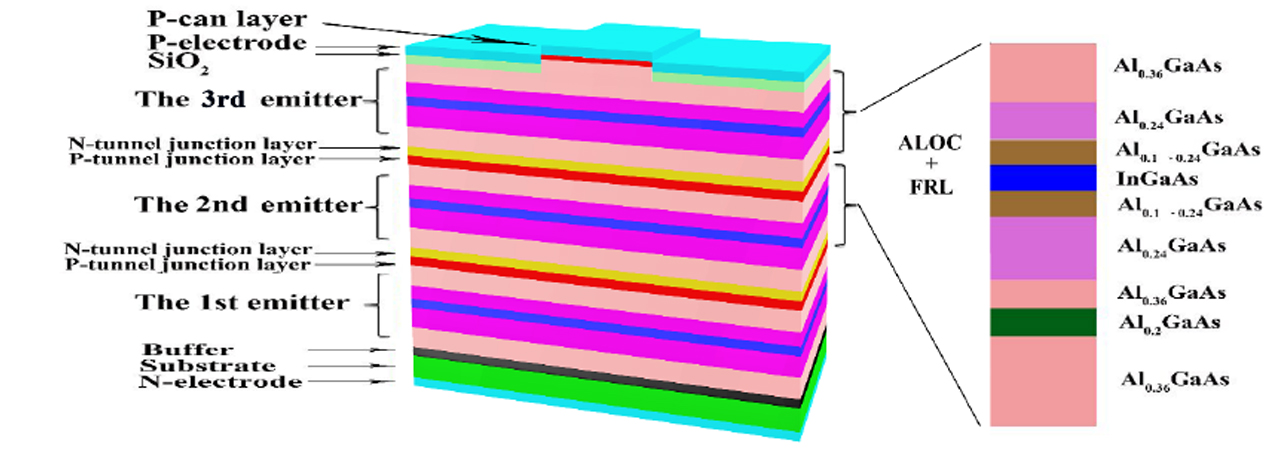

For higher power output, the design of multiple light-emitting sections is generally adopted in the industry.

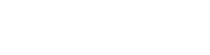

Ripple Optoelectronics offers a number of different diode laser solutions, each offering specific advantages depending on the application and type of 3D sensing solution deployed (time-of-flight, structured light, etc.).

Ripple Optoelectronics provides 905nm edge-emitting lasers, with light-emitting sections ranging from single, three to four, for TOF lidar, and also provides 905nm 1*4/1*8 array chips for line light sources. Ripple Optoelectronics also provides 1550nm direct semiconductor lasers for short-distance laser ranging. In addition, Ripple Optoelectronics also provides 940nm pump chips for 1550nm MOPA. With scalable manufacturing scale, these diode lasers deliver high throughput, consistent reliability and excellent product quality.

To learn more about Ripple Optoelectronics lasers and technologies, please contact Ripple Optoelectronics Sales.